Forging can be carried out by many methods, some of which are listed below:

Rolling

Rolling Practice

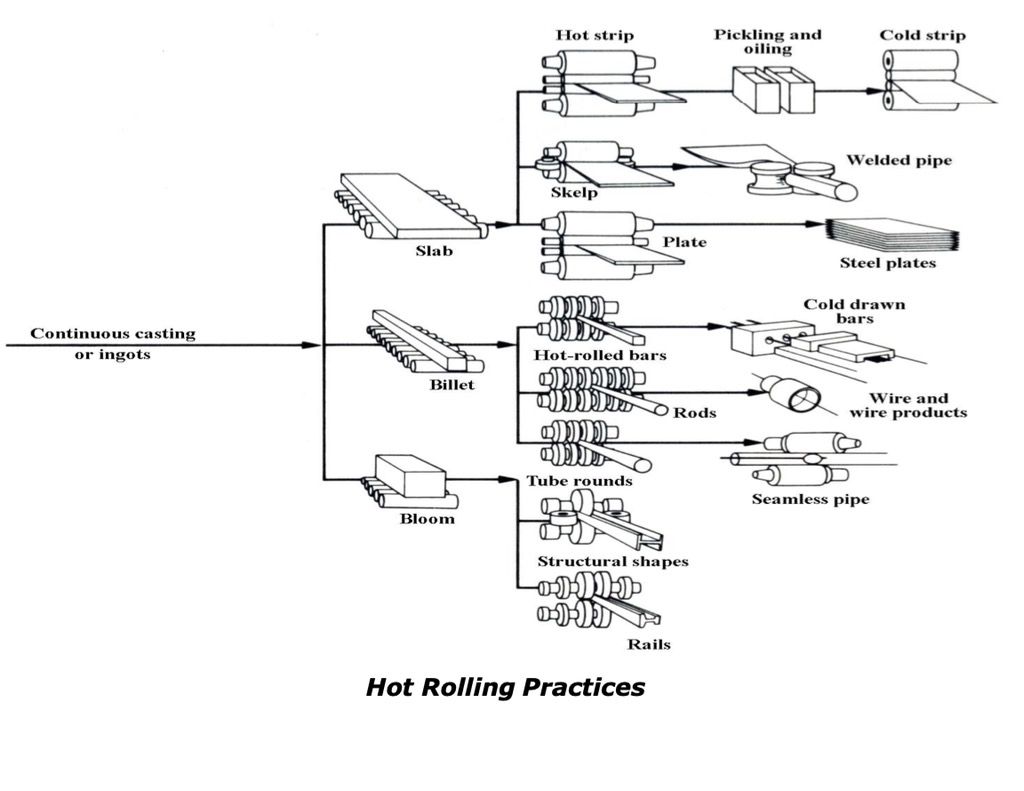

When an ingot or continuously cast section is to be further processed, the first operation is usually rolling. Rolling modifies the shape to one that can be either the finished product or is suitable for further processing.

Rolling also modifies and homogenises the structure from the as cast state.

- Cogging to change form and structure from an ingot in to a bloom.

Primary rolling (roughing/cogging*) is usually only applied to ingots to bring them to a suitable size and shape. This size and shape may also be a direct product of continuous casting so concast products are not subject to primary rolling.

Further stages of rolling (secondary) produce progressively more useful shapes. The product of this rolling may be blooms, billets, slabs, plate**, I or H beams.

**Plate going to be 30 further worked to form pipe is referred to as “Skelp”

Blooms, billets and slabs

- Square bloom – Semi-finished product with sides generally greater than 120 mm.

- Rectangular bloom – Semi-finished product with cross sectional area greater than 14,400 mm2 and with a ratio of width to thickness greater than 1:1 and less than 2:1.

- Square billet – Semi-finished product with sides generally equal to or greater than 50 mm and less than or equal to 120 mm.

- Rectangular billet – Semi-finished product with cross-sectional area equal to or greater than 2500 mm2 and less than or equal to 14,400 mm2 and with a ratio of width to thickness greater than 1:1 and less than 2:1.

- Round billet – Semi-finished product with diameter equal to or greater than 75 mm. (Up to 75 mm is termed round bar).

- Slab – Semi-finished product of thickness equal to or greater than 50 mm and with a width to thickness ratio equal to or greater than 2:1.

- Flat slab – Slab with a width to thickness ratio greater than 4:1.

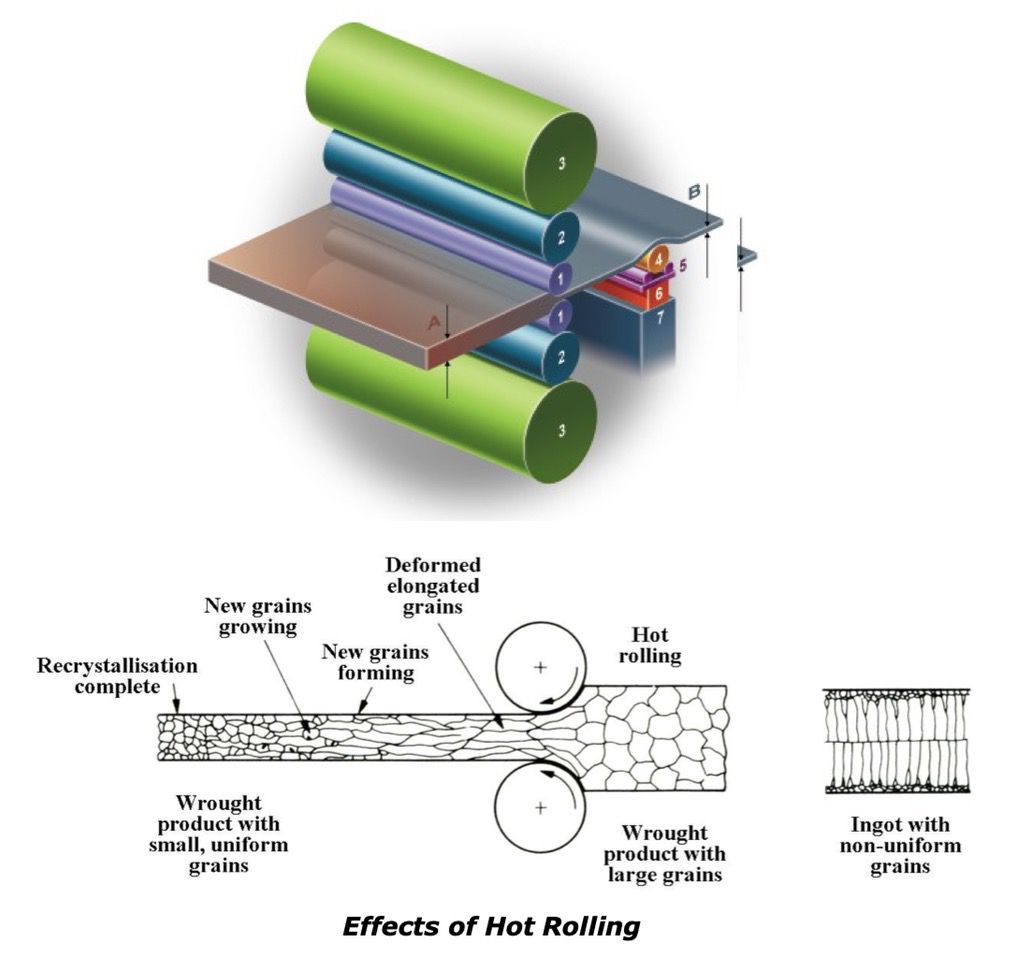

Rolling may be carried out ‘hot’ or ‘cold’. Hot means that the process is carried out at a temperature above the ‘recrystallisation’ temperature. Above this temperature, grains that have been distorted and elongated are re-formed as small equiaxed grains. Rolling temperature is critical as grain growth continues at higher temperatures which could lead to excessive grain size and consequently weak material.

From the above simple shapes a multitude of end products may be produced.

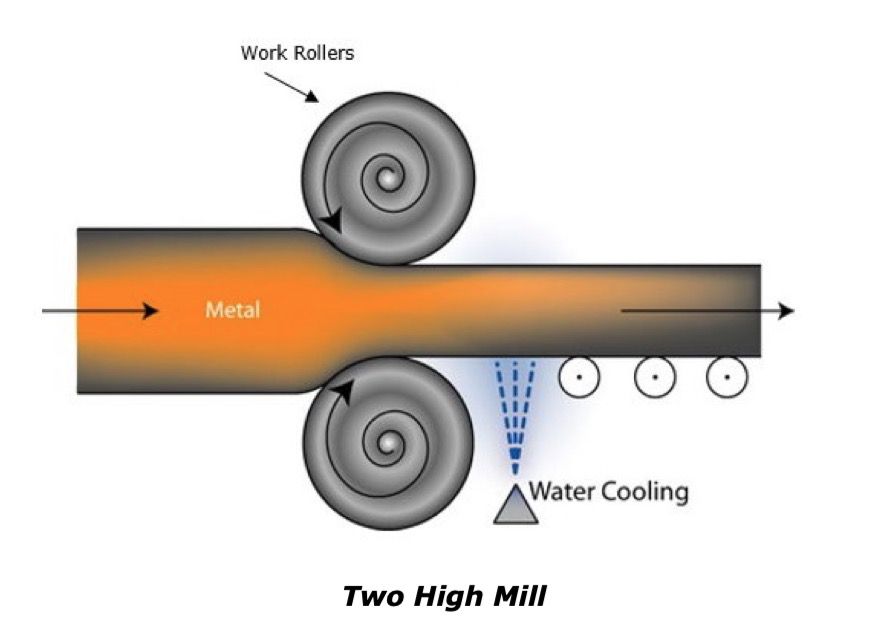

Primary rolling usually takes place between a pair of large diameter *work rolls, the arrangement being called ‘2 high’. Each pair of rolls is held in a ‘stand’. Rolling may take place back and forth through these rolls (reversing mill) or through a series of roll stands (roll train).

- The term ‘work roll’

contact with the material

being worked, whereas a

back up roll is only in 90

contact with a work roll to

stop distortion and

improve mechanical

tolerances on the finished

product – both types of roll may be manufactured as a casting or a wrought 100 product.

As thickness is decreased the length will increase. Initial (primary) rolling from ingot (or concast billet or bloom) is carried out hot and reductions in thickness of over 50mm per pass can be achieved.

Hot rolling is carried out initially to make the material easier to deform and to allow modification of the structure to enhance properties. Ingots are preheated in a soaking pit to around 1300 degrees C. When hot working steel the material reacts with the oxygen in the atmosphere creating scale on the material surface and has to be periodically removed to avoid being rolled back in to the surface, this is achieved by

- Scale busting rolls i.e. the plate is bent then straightened and the hard inflexible scale breaks off

- “Scarfing” a generic term for using heat to remove surface imperfections, in this case scale has a different coefficient of expansion and contraction rate to the base steel and falls away, sometimes with a tremendous release of energy.

- Blasting, normally with water not at high pressure but simply to induce a cooling effect, giving a net result similar to scarfing.

- Other techniques may include pickling (acid) or mechanical techniques such as wire brushing, grinding, needle guns or machining. The process is carried out between two large rolls (up to 50 inches in diameter and each weighing up to 20 tons) called a “two high mill”.

These may be reversing rolls with reductions taking place on consecutive passes through the rolls in opposite directions. Width is controlled by side rolls.

From this stage the steel goes to “three high mills” which are not reversing, the direction being changed by raising or lowering a table. These use less power and have less wear and tear as they run continuously in one direction.

As the process continues, more accuracy is needed and rolls are given backing rolls to control distortion. Mill stands then become ‘4 high’, ‘6 high’ or may be complicated ‘cluster mills’ with 20+ rolls in them for producing thin foil.

For greater control over dimension, surface finish and properties, a cold rolling process is carried out which will use mills having four or more rolls per set.

By using smaller work rolls there is less surface area in contact with the metal and less energy required but to prevent bending (and maintain dimensional tolerances) backing rolls are used.

Cold rolling gives good dimensional control and surface finish. Cold working is the strengthening of a metal by plastic deformation. The strengthening occurs because of the dislocation movement and dislocation generation within the crystal structure of the material. This can also be known as work hardening or strain hardening.